Samudra Scale — Legacy Weighbridge Modernization

🏗 Project Context

This project focuses on the digital transformation of a heavy-duty truck weighbridge system at PT. Keramindo Megah Pertiwi. Originally installed in 1998, the system lacked modern data interfaces, making it difficult to integrate with current logistics and reporting software. I developed a complete end-to-end solution to bridge this 28-year technology gap without requiring expensive hardware overhauls.

🚀 The Solution: Legacy to Cloud

The core of the solution is a hardware-software bridge that transforms raw industrial signals into actionable business intelligence. It effectively digitizes data that was previously isolated within the local scale hardware.

| Layer | Implementation |

|---|

| Edge Hardware | Raspberry Pi 3 acting as a gateway to intercept RS-232/236 serial streams. |

| Logic Layer | Real-time byte translation using the specialized samudra-scale Python library. |

| Application | A centralized web dashboard for vehicle management and automated logistics reporting. |

🛠 Technical Implementation

Real-Time Data Translation

The primary technical challenge was decoding the proprietary byte format of the legacy scale. I engineered the samudra-scale library to map these specific byte sequences into numeric values, enabling accurate real-time monitoring of truck payloads.

from samudra_scale import decode_bytes

# Intercepted raw data from 1998 legacy hardware

data = b'S\xd4\xacGS\xac+\xa000\xb8950\xeb\xe7\x8d\n'

# Real-time decoding into KG

weight = decode_bytes(data)

print(f"Current Payload: {weight} KG") # Output: 8950

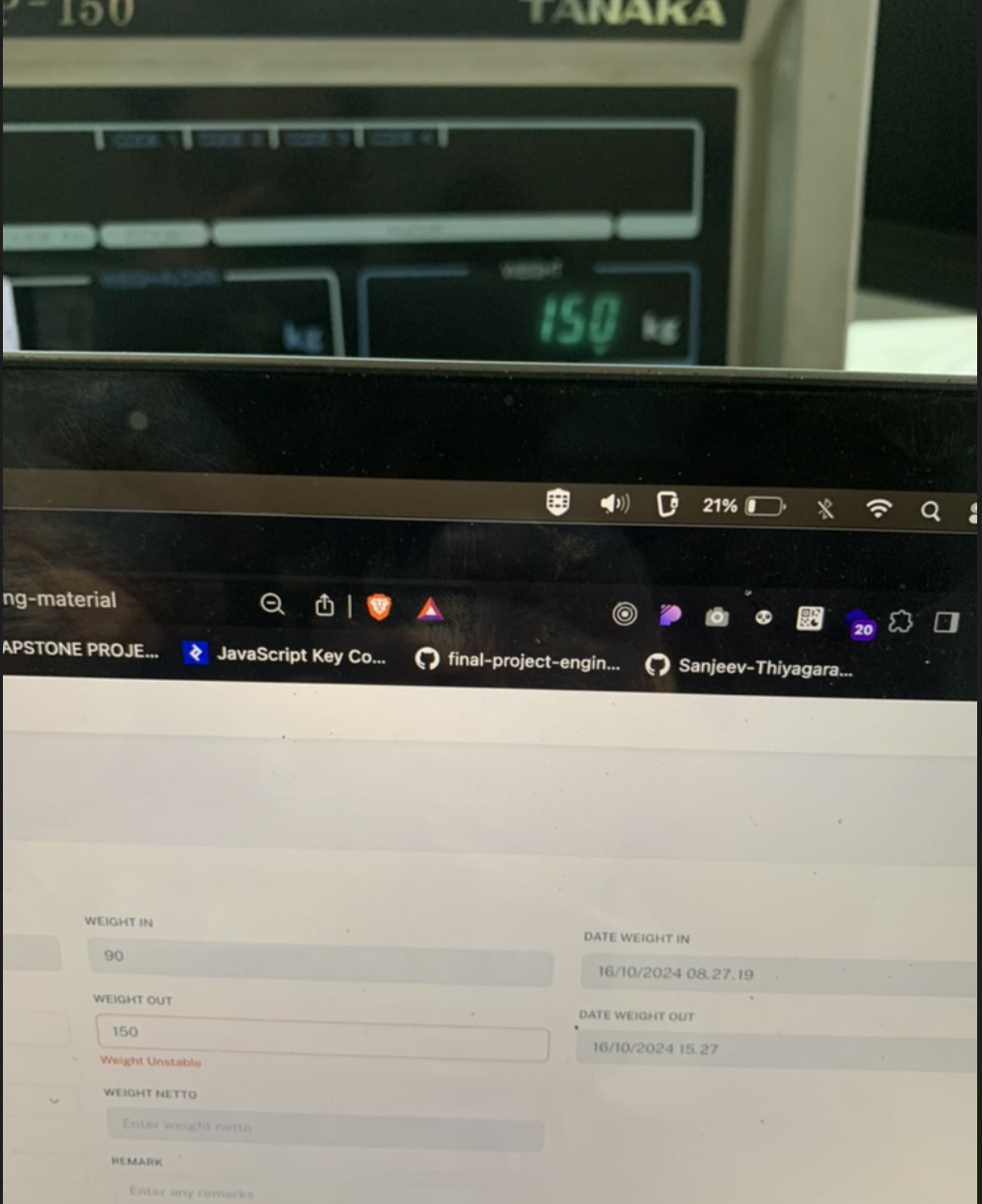

Digital Management Dashboard

The integrated app provides a modern UI to manage the entire weighbridge lifecycle:

- Vehicle Tracking: Automated logging of entry/exit times and truck IDs.

- Weight Calculation: Precision monitoring that accounts for tare weight and cargo variables.

- Instant Reporting: Exportable data for supply chain and inventory audits.

✨ Key Impact

- Infrastructure Longevity: Modernized 1998 hardware without the need for high-cost equipment replacement.

- Real-Time Accuracy: Eliminated manual logging errors through automated Raspberry Pi data capture.

- Data Accessibility: Centralized all weighbridge activity into a single, accessible web platform.

💻 Tech Stack

- IoT Hardware: Raspberry Pi 3 (Embedded Linux).

- Protocols: RS-232/236 Serial Communication.

- Library: samudra-scale (Proprietary/Public Hybrid).

- Software: Node.js & Next.js for the Management Dashboard.